Automatic self-loading mixer trucks have revolutionized the concrete industry with their efficiency, versatility, and ease of operation. These innovative machines are equipped with advanced automation and technology features that streamline the concrete production process, making them ideal for a wide range of construction projects.

1. Understanding the Basics of Automatic Self-Loading Mixer Trucks

Before operating an automatic self-loading mixer truck, it’s essential to understand the basic components and functionalities of the self loading concrete mixer with pump. These trucks are equipped with a mixing drum, loading hopper, hydraulic loading arms, and an onboard control system. The mixing drum rotates to blend aggregates, cement, and water into concrete, while the hydraulic loading arms are used to load materials into the drum. The onboard control system allows operators to monitor and control various parameters of the mixing and loading process.

2. Pre-Operation Inspection and Maintenance

Prior to operating an automatic self-loading mixer truck, conducting a thorough pre-operation inspection is critical to ensure the safety and functionality of the machine. Operators should inspect the truck for any signs of damage, leaks, or worn components. This includes checking hydraulic hoses, connections, and fittings, inspecting the mixing drum and discharge chute for cleanliness and proper operation, and verifying fluid levels and tire pressures. Any issues or abnormalities should be addressed promptly to prevent accidents or equipment failures during operation.

3. Familiarizing Yourself with the Controls

Automatic self-loading mixer trucks are equipped with a range of controls and settings that allow operators to adjust various parameters of the mixing and loading process. It’s essential to familiarize yourself with these controls before operating the self mixing concrete truck. This includes understanding how to start and stop the engine, engage the mixing drum, operate the hydraulic loading arms, and adjust the speed and direction of the truck. Proper training and familiarization with the controls ensure safe and efficient operation of the mixer truck.

4. Loading Aggregates, Cement, and Water

Loading materials into the mixing drum of a self-loading mixer truck is a straightforward process, thanks to the hydraulic loading arms and automated controls. Operators can use the controls to position the loading hopper over the materials to be loaded, such as aggregates, cement, and water. The hydraulic loading arms then scoop up the materials and deposit them into the mixing drum. It’s essential to ensure that the correct proportions of materials are loaded to achieve the desired concrete mix.

5. Mixing Concrete

Once the materials are loaded into the mixing drum, the automatic self-loading mixer truck’s onboard control system allows operators to initiate the mixing process. The mixing drum rotates at variable speeds to thoroughly blend the aggregates, cement, and water into concrete. Operators can monitor the mixing process via the onboard control panel and adjust parameters such as drum speed and mixing time as needed to achieve the desired concrete consistency.

6. Discharging Concrete

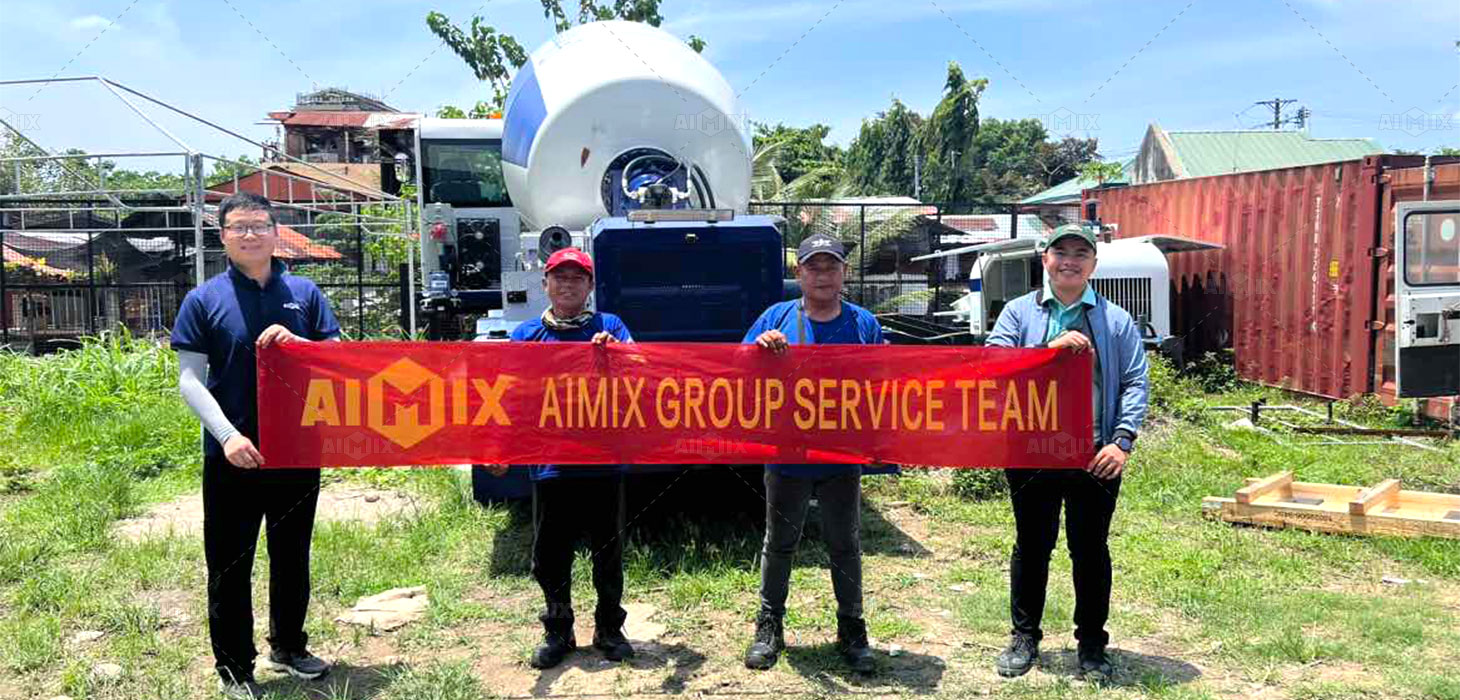

After the concrete has been thoroughly mixed, it’s ready for discharge from the mixer truck. Automatic aimix self loading concrete mixers are equipped with hydraulic discharge chutes that allow operators to control the flow and direction of the concrete as it is discharged from the drum. Operators can use the onboard controls to position the discharge chute over the desired location for concrete placement, whether it’s into formwork, onto the ground, or into a concrete pump for further placement.

7. Safety Considerations

Safety should always be a top priority when operating an automatic self-loading mixer truck. Operators should adhere to all safety guidelines and protocols established by the manufacturer and regulatory authorities. This includes wearing appropriate personal protective equipment, such as safety goggles, gloves, and steel-toed boots, and following proper procedures for machine operation and maintenance. Additionally, operators should be aware of their surroundings and take precautions to prevent accidents, such as ensuring proper clearance when operating the hydraulic loading arms and discharge chute.

8. Regular Maintenance and Servicing

To ensure the reliable and efficient operation of an automatic self-loading mixer truck, regular maintenance and servicing are essential. Operators should follow the manufacturer’s recommended maintenance schedule for tasks such as fluid changes, filter replacements, and component inspections. Any signs of wear, damage, or malfunction should be addressed promptly to prevent equipment downtime and maintain optimal performance.

Conclusion

Operating an automatic self loading mobile concrete mixer requires a combination of technical knowledge, operational skill, and safety awareness. By understanding the basics of the machine, conducting thorough pre-operation inspections, familiarizing yourself with the controls, loading and mixing materials accurately, discharging concrete safely, and adhering to proper maintenance practices, operators can ensure the efficient and reliable operation of automatic self-loading mixer trucks in construction projects.