When purchasing a double girder gantry crane for your project, price is a critical factor. These cranes are designed for heavy-duty applications and can involve a significant investment. Negotiating effectively with manufacturers not only helps you secure a better deal but also ensures you get a high-quality product that fits your needs. Here are practical tips for negotiating the double girder gantry crane price with manufacturers.

Research Market Prices

Before entering into negotiations, understand the market pricing for double girder gantry cranes.

Compare Quotes: Request quotes from multiple manufacturers to establish a price range.

Check Online Listings: Look for price references on manufacturer websites or industry platforms.

Consider Regional Variations: Prices may vary depending on the manufacturer’s location and the cost of raw materials.

Being informed about market prices gives you a baseline for discussions and helps you identify fair pricing.

Clearly Define Your Requirements

Specific project requirements directly impact the crane’s price. Providing gantry crane manufacturers with clear details helps avoid unnecessary costs.

Load Capacity: Specify the maximum weight the crane will lift.

Span and Lifting Height: Provide dimensions to ensure the crane is appropriately sized.

Operational Features: Indicate whether you need custom features like remote control, automation, or additional safety mechanisms.

Environmental Considerations: Let the manufacturer know if the crane will operate in harsh environments, as this may require specialized materials or coatings.

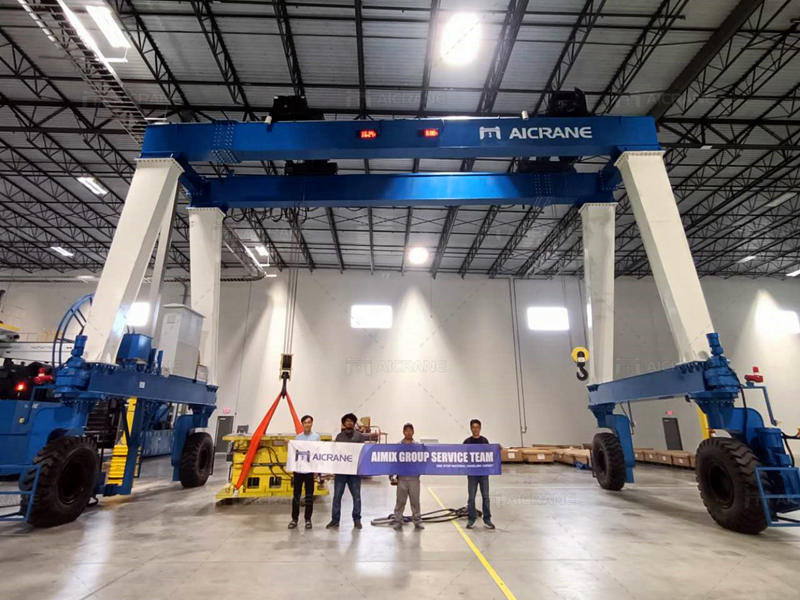

A clear understanding of your needs ensures the manufacturer like Aicrane can provide an accurate and tailored quote.

Understand Cost Drivers

Knowing what affects the price of a double girder gantry crane helps you focus your negotiations.

Materials: The cost of steel and other materials significantly impacts pricing.

Technology: Advanced features like automated systems or anti-sway technology can increase costs.

Customization: Cranes designed for specific applications may require additional engineering work, which affects the price.

Delivery and Installation: Transportation fees and installation services add to the total cost.

Understanding these elements allows you to negotiate specific aspects of the price effectively.

Build a Good Relationship with the Manufacturer

Developing a positive relationship with the manufacturer can give you an edge during negotiations.

Engage Early: Start discussions early to demonstrate your serious intent to purchase.

Ask Questions: Show interest in the manufacturer’s expertise by asking technical questions.

Communicate Clearly: Be respectful and professional in all communications.

Building trust can lead to better discounts, priority service, and additional benefits like extended warranties.

Discuss Bulk Orders or Long-Term Partnerships

If you anticipate purchasing additional equipment in the future, leverage this during negotiations.

Bulk Discounts: Ask if the manufacturer offers price reductions for bulk orders.

Future Business Opportunities: Highlight the potential for long-term collaboration, which may motivate the manufacturer to offer better terms.

Positioning yourself as a repeat customer can make the manufacturer more willing to negotiate.

Negotiate Additional Value, Not Just Price

While focusing on price is essential, other factors can add significant value to your purchase.

Extended Warranty: Negotiate for longer warranty periods or enhanced coverage.

Free Spare Parts: Request additional spare parts to reduce future maintenance costs.

Installation Services: Ask for discounts on installation or training services.

Faster Delivery: Negotiate expedited delivery without extra charges.

By discussing value-added benefits, you can maximize the overall deal.

Request Detailed Quotes

Ask the manufacturer to provide a comprehensive breakdown of the price.

Itemized Costs: Ensure the quote specifies the cost of materials, labor, transportation, and installation.

Customization Fees: Verify additional charges for special features or modifications.

Hidden Costs: Check for any hidden fees, such as taxes or import duties.

A transparent quote makes it easier to identify areas where you can negotiate.

Leverage Competitive Offers

Use quotes from other manufacturers as leverage during negotiations.

Present Alternatives: Politely mention better offers you’ve received and ask if the manufacturer can match or beat them.

Avoid Unrealistic Demands: Be reasonable in your comparisons to maintain credibility.

Focus on Quality: Emphasize that while you value competitive pricing, quality remains your priority.

Strategically mentioning competition can encourage the manufacturer to provide a more attractive price.

Negotiate Payment Terms

Payment terms can significantly impact your overall budget.

Installment Plans: Request to pay in stages, especially for large projects.

Early Payment Discounts: Ask if upfront payments qualify for additional discounts.

Flexible Payment Schedules: Negotiate terms that align with your cash flow.

Favorable payment terms can make the purchase more manageable and cost-effective.

Verify Manufacturer Credentials

Ensure the manufacturer is reputable and capable of delivering high-quality cranes.

Certifications: Confirm compliance with industry standards like ISO, CE, or ASME.

Customer Reviews: Read reviews or request references from previous clients.

Inspection Opportunities: Visit the manufacturer’s facility or inspect their completed projects.

Working with a trusted manufacturer reduces risks and strengthens your position during negotiations.

Time Your Purchase Wisely

Timing can influence the price of a double girder gantry crane.

Off-Peak Periods: Manufacturers may offer discounts during slower production periods.

Promotions and Trade Shows: Look for special deals during trade events or seasonal sales.

Market Trends: Monitor raw material costs, as fluctuations can affect crane prices.

Strategic timing can help you secure a better deal.

Be Prepared to Walk Away

If negotiations stall or the manufacturer refuses to meet reasonable terms, be ready to explore other options.

Set a Budget: Define your maximum spending limit before negotiations.

Have Alternatives Ready: Maintain a list of other manufacturers to approach.

Stay Polite: Leave the door open for future discussions if circumstances change.

Knowing when to walk away demonstrates confidence and prevents overspending.

Negotiating the double girder gantry crane price with a manufacturer requires preparation, clarity, and strategy. By understanding your project needs, researching market trends, and focusing on value-added benefits, you can secure the best deal while maintaining quality. Building a strong relationship with the manufacturer and exploring flexible payment options further enhance your negotiation success. With these tips, you’ll be well-equipped to purchase a crane efficiently and cost-effectively.