Setting up a crushing and screening plant is a critical step in the construction and mining industries, where efficient material processing is essential for success. These crusher plants are designed to handle large quantities of raw materials, turning them into various grades of aggregate required for construction projects, road building, and more. To ensure optimal performance and long-term viability, it’s crucial to follow best practices, select top solutions, and adhere to essential guidelines. This article delves into these key aspects to help you set up a crushing and screening plant that delivers consistent results and high productivity.

Best Practices for Setting Up a Crushing and Screening Plant

Site Selection and Layout Planning

Choosing the right location for your crushing and screening plant is one of the most important decisions you’ll make. The site should be easily accessible, with ample space for machinery, stockpiles, and transportation routes. Proximity to the source of raw materials is another critical factor, as it can significantly reduce transportation costs and time. Additionally, considering the local environmental regulations and zoning laws is essential to avoid future legal complications.

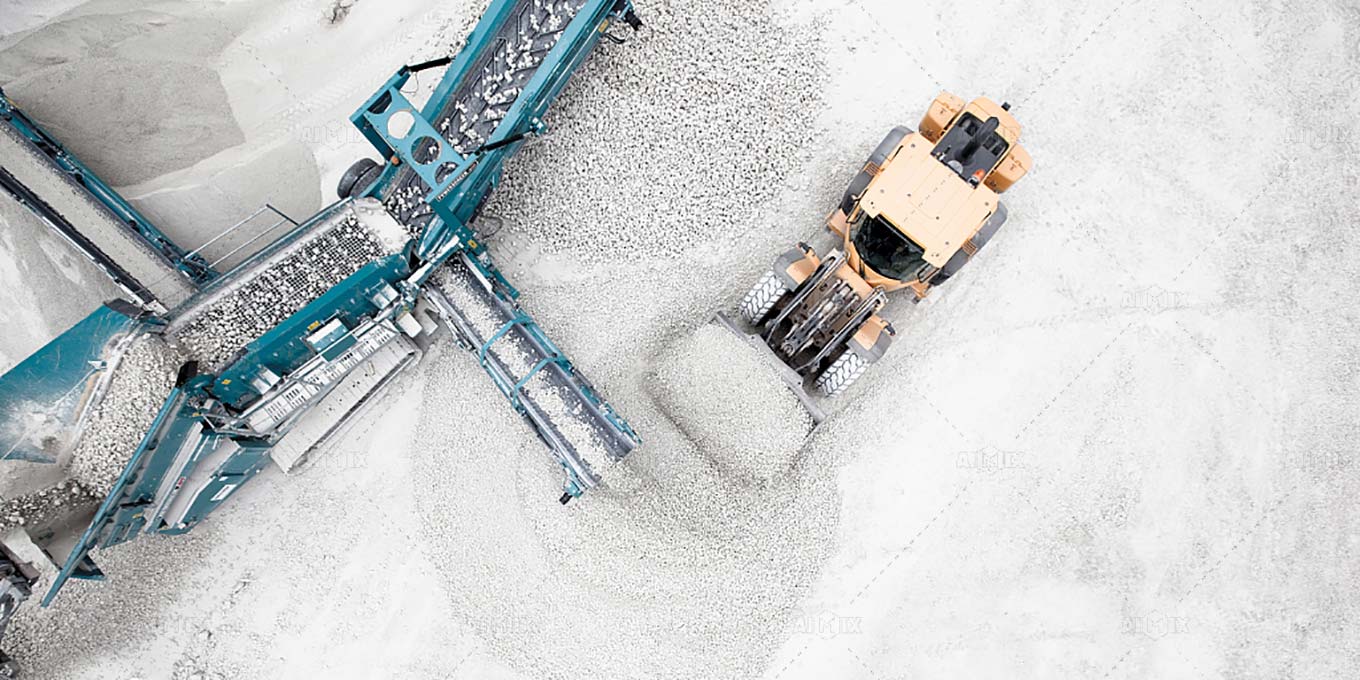

Once the site is selected, a well-thought-out layout is crucial for efficient plant operations. The layout should facilitate smooth material flow, minimizing the need for excessive handling or transportation. Placing the crushers and screens in a sequence that allows for efficient material processing can significantly enhance productivity. Adequate space for stockpiles, waste management, and future expansion should also be incorporated into the layout design.

Equipment Selection and Compatibility

Selecting the right equipment is paramount for the success of your crushing and screening plant. The choice of crushers, screens, conveyors, and other ancillary equipment should be based on the type of material you intend to process and the desired output. Factors such as feed size, hardness of the material, and required production capacity should guide your equipment selection.

Equally important is ensuring compatibility among all the plant components. Incompatible equipment can lead to operational inefficiencies, increased wear and tear, and ultimately higher maintenance costs. It’s advisable to consult with AIMIX crusher plant manufacturer or industry experts to ensure that all components work seamlessly together.

Top Solutions for Crushing and Screening Plant Setup

Advanced Technology Integration

In today’s competitive environment, integrating advanced technology into your crushing and screening plant is not just an option; it’s a necessity. Automation and control systems can optimize plant operations by regulating feed rates, monitoring machine performance, and adjusting settings in real time. This not only improves efficiency but also reduces human error and downtime.

Examples of cutting-edge technologies include automated crushers that adjust their settings based on the material being processed, and smart screens that can change their screening parameters dynamically. Incorporating these technologies can significantly boost plant productivity and ensure consistent output quality.

Cost-Effective and Sustainable Solutions

The initial setup cost of a crushing and screening plant can be substantial, but focusing on cost-effective solutions can help manage expenses without compromising performance. Opting for modular plants that can be easily assembled and disassembled is one way to reduce installation costs. These plants are also easier to transport and set up at new sites, offering greater flexibility.

Sustainability is another crucial factor in today’s industry landscape. Implementing solutions that minimize energy consumption, reduce emissions, and promote recycling can help lower operational costs while meeting environmental standards. Many top-selling solutions in the market now include energy-efficient mobile crushing and screening plant, dust suppression systems, and waste recycling mechanisms.

Essential Guidelines for Optimizing Plant Performance

Maintenance and Safety Protocols

Regular maintenance is vital to keep your crushing and screening plant running smoothly. Scheduled inspections, timely replacement of wear parts, and keeping the machinery well-lubricated can prevent unexpected breakdowns and prolong equipment life. Moreover, a well-maintained plant operates more efficiently, leading to lower operational costs and higher output.

Safety should always be a top priority. Implementing comprehensive safety protocols protects both your personnel and your equipment. Ensure that all workers are trained in the safe operation of machinery and that safety features like emergency stop buttons, guards, and alarms are in place and functioning. Regular safety audits can help identify potential hazards before they lead to accidents. Check more operation details on this page: https://aimixgroup.com/stone-crusher-plants/.

Continuous Monitoring and Improvement

To ensure that your crushing and screening plant operates at its full potential, continuous monitoring and improvement are necessary. This involves tracking key performance indicators (KPIs) such as production rates, fuel consumption, and equipment utilization. Analyzing this data can reveal areas where improvements can be made, whether through process optimization, equipment upgrades, or changes in operational procedures.

By following these guidelines and best practices, you can set up a crushing and screening plant that not only meets your current needs but also has the flexibility to adapt to future challenges and opportunities.